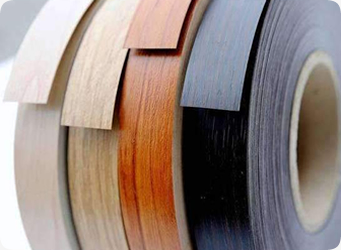

Eastern Panel uses only the highest quality plywood for laminating to ensure a balanced product. Our state of the art facility is complete with automatic panel lines. Manufacturing projects are completely customizable to your choice of venner and laminate.